In the printing world, sublimation ink’s versatility for regular printing has intrigued many. Discover its potential today!. As the printing landscape evolves, individuals and businesses are curious about pushing the boundaries of traditional printing methods. Explore sublimation ink: pros, cons, and creative uses in regular printing. Discover its compatibility and unique possibilities.

Can You Use Sublimation Ink for Regular Printing?

Sublimation ink is celebrated for its brilliance and longevity on specially coated substrates like polyester fabric. However, can it be repurposed for standard printing tasks using regular paper? The answer lies in several key considerations:

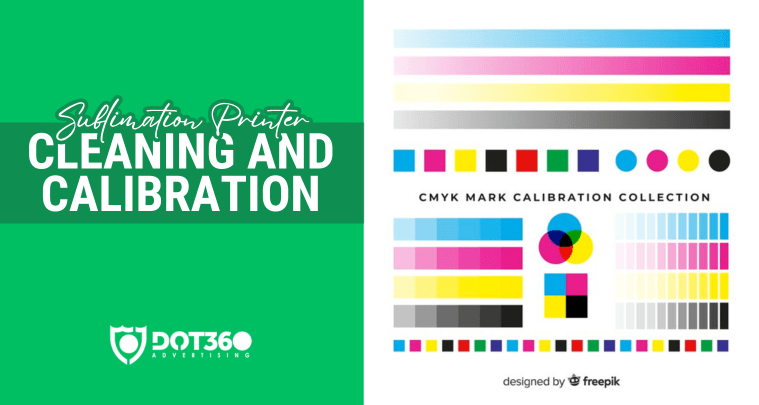

- Chemical Composition Compatibility: Sublimation ink is engineered to transition from solid to gas through heat, bonding with polyester molecules. Regular printing paper lacks this specialized coating, preventing the chemical reaction necessary for optimal results.

- Print Head Suitability: Regular and sublimation printing devices differ in print head design and ink viscosity. Attempting to use sublimation ink in a regular printer could lead to clogs and damage due to these variations.

- Color Brilliance and Accuracy: Sublimation ink is acclaimed for its vivid colors and accuracy, attributed to its unique chemical makeup. However, these characteristics might not translate perfectly onto standard printing paper.

- Durability and Resilience: Sublimation ink’s durability shines when used on substrates with the appropriate coating. Regular paper lacks this coating, resulting in prints that might fade over time.

- Transfer Process Complexity: Sublimation printing involves a two-step process with heat transfer, which regular printers are not equipped for. This process includes transferring the ink from paper to the final substrate, a concept foreign to standard printing methods.

Exploring the Benefits of Sublimation Ink for Regular Printing

While sublimation ink and regular printing processes have inherent differences, there are situations where their convergence can yield unique benefits:

- Artistic Expression: By printing sublimation ink on specially coated craft paper, you can create captivating artworks and crafts that infuse the vibrancy of sublimation ink into creative projects.

- Hybrid Designs: Combining the vivid imagery of sublimation ink with the text-based clarity of regular printing can result in eye-catching business cards, invitations, and other printed materials.

- Precision Prototyping: Sublimation ink could be valuable for prototyping designs that demand precise color representation. Testing with sublimation ink gives you insights into color accuracy before final production.

- Small-Scale Specialization: For limited print runs of visually striking materials, the marriage of sublimation ink’s vibrancy and the convenience of regular printing could be a game-changer.

The Limitations You Need to Acknowledge

Before embarking on sublimation ink for regular printing, it’s vital to acknowledge the limitations that come with this unconventional approach:

- Image Quality: Achieving the same level of image quality and color accuracy on regular paper is challenging. The chemical reaction that underpins sublimation ink’s brilliance is tailored for specific substrates.

- Longevity Concerns: Sublimation ink’s durability on standard paper might fall short of expectations. Regular paper lacks the coating necessary to maintain the ink’s vibrancy over time.

- Cost Implications: Sublimation ink is an investment, and using it beyond its intended purpose could lead to waste, especially considering the complexity of the transfer process.

- Printer Compatibility: Attempting to use sublimation ink on a regular printer risks damaging the printer’s components and voiding warranties, potentially incurring additional costs.

Is It Possible to Use Sublimation Ink for Regular Printing?

Yes, it is possible to use sublimation ink for regular printing, but the results may not match those of regular ink in terms of quality and color vibrancy. Sublimation ink is designed to be transferred through heat onto sublimation-coated materials and polyester fabric. Unique chemistry and transfer process limit performance on standard paper compared to other printing methods.

Conclusion

The intersection of sublimation ink and regular printing methods invites both curiosity and creativity. While using dye-sub ink for regular printing is feasible, it comes with inherent limitations that must be considered. The potential for artistic endeavors and specialized applications is enticing, but it’s essential to recognize that sublimation ink’s true prowess shines when used on its intended substrates. In the realm of printing possibilities, the fusion of these two worlds sparks innovation, reminding us that while boundaries exist, so do opportunities for exploration and ingenuity.