Sublimation printing is a versatile and popular method for transferring vibrant and long-lasting designs onto various surfaces, from clothing to promotional items. However, like any printing process, it comes with its fair share of challenges. Troubleshooting common sublimation printing issues is essential to achieving consistent, high-quality results. In this comprehensive guide, we will delve into the world of dye-sub printing troubleshooting. Whether you’re a seasoned professional or just starting with sublimation, this article will equip you with the knowledge and expertise to overcome common issues and ensure your prints turn out flawless every time.

Troubleshooting Common Sublimation Printing Issues

Sublimation printing issues can be frustrating, but with the right knowledge and techniques, you can address and prevent them effectively. Let’s explore these issues and their solutions in detail:

Insufficient Color Vibrancy

Achieving vibrant and accurate colors is the essence of sublimation printing. When your prints lack the desired color intensity, it can be disappointing. To troubleshoot this issue:

- Check Your Heat Press Temperature: Ensure that your heat press is set to the recommended temperature for the sublimation ink and material you are using. Inconsistent temperature can result in dull colors.

- Use Quality Sublimation Ink: Invest in high-quality sublimation ink cartridges. Inferior ink can lead to faded prints.

- Evaluate Transfer Time: Adjust the pressing time according to your substrate. Too short or too long can affect color saturation.

Blurred or Ghosted Images

Blurry or ghosted images can ruin the visual appeal of your sublimation prints. Here’s how to address this issue:

- Inspect Your Substrate: Make sure the material you’re printing on is clean and free from any residue or wrinkles.

- Check for Head Clogs: If using a dye-sub printer, inspect and clean the print heads regularly to prevent ink dispersion issues.

- Confirm Design Resolution: Ensure your design files have a high resolution (at least 300 DPI) to avoid pixelation.

Uneven Color Distribution

Uneven color distribution can result in patchy or streaky prints. To tackle this problem:

- Maintain Pressure Uniformity: Ensure that your heat press exerts even pressure across the entire printing area.

- Use Proper Sublimation Paper: Select sublimation paper that is compatible with your printer and ink. Low-quality paper can cause uneven ink absorption.

- Adjust Ink Saturation: Experiment with ink saturation settings to find the right balance between vivid colors and even distribution.

Fading Over Time

Sublimation prints are known for their durability, but they can still fade over time if not done correctly. Prevent fading with these tips:

- Choose Quality Materials: Use substrates and fabrics that are specifically designed for dye-sub printing to ensure longevity.

- Apply Heat Evenly: Pay attention to the heat distribution during the pressing process. Ensure that the entire design receives consistent heat.

- Follow Proper Washing Instructions: Instruct your customers on how to care for sublimation-printed items. Avoid harsh detergents and hot water.

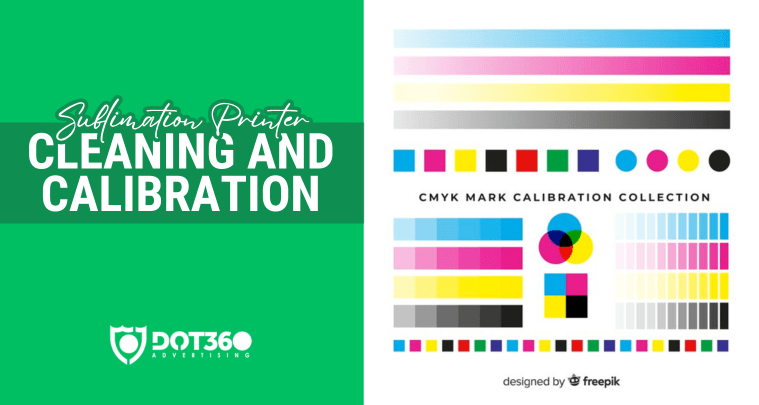

Color Shifting

Color shifting occurs when the colors in your print do not match the original design. To counteract this issue:

- Calibrate Your Printer: Regularly calibrate your sublimation printer to maintain color accuracy.

- Control Ambient Humidity: Fluctuations in humidity can affect dye-sub ink behavior. Use a dehumidifier if necessary.

- Optimize Color Profiles: Experiment with color profiles to achieve the closest match to your desired colors.

- Color Calibration: Ensures that your printer reproduces colors accurately by adjusting the ink output to match your desired color profiles. (For those sublimation printers that are using 3rd-party ink, color calibration is a must. Watch below the tutorial on how to do color calibration on your 3rd-party ink)

How to Calibrate Sublimation Printer (step-by-step) | Color Correction | Color Problem SOLVED

Conclusion

Troubleshooting common sublimation printing issues is an essential skill for anyone involved in sublimation printing. By addressing issues related to color vibrancy, image quality, color distribution, fading, and color shifting, you can ensure that your dye-sub prints consistently meet your expectations. Remember to use high-quality equipment, materials, and inks, and don’t hesitate to experiment and fine-tune your settings to achieve the best results. With the insights and solutions provided in this guide, you’ll be well-equipped to tackle any sublimation printing challenge that comes your way.

Happy printing! By following these expert tips and insights, you’ll be well-prepared to troubleshoot common sublimation printing issues and achieve stunning, long-lasting results in your sublimation projects.

Additionally, for further information and resources on sublimation printing, you can visit Wikipedia’s Sublimation Printing Page. So, whether you’re a seasoned sublimation professional or just starting on your dye-sub journey, this guide will help you navigate and conquer the challenges of sublimation printing, ensuring your creations are always picture-perfect and vibrant.

Frequently Asked Questions (FAQs)

Let’s address some common queries about troubleshooting sublimation printing issues:

Q1. What Are the Key Components of a Sublimation Printing Setup?

A1. In a sublimation printing setup, you’ll need a sublimation printer, sublimation ink, sublimation paper, a heat press, and the substrate or material you intend to print on. Each of these components plays a crucial role in the printing process.

Q2. How Can I Prevent Sublimation Prints from Fading?

A2. To prevent sublimation prints from fading, use high-quality materials, apply even heat during pressing, and educate your customers on proper care methods. Following these steps will ensure your prints remain vibrant for an extended period.

Q3. Why Do My Sublimation Prints Appear Dull?

A3. Dull sublimation prints can be the result of incorrect heat press temperature, low-quality ink, or inadequate transfer time. Ensure you’ve optimized these factors to achieve the desired vibrancy in your prints.

Q4. What Causes Ink Blotches in Sublimation Printing?

A4. Ink blotches can occur due to clogged print heads or uneven ink distribution. Regularly clean your print heads and ensure even pressure during the heat press process to avoid this issue.

Q5. Can I Print on Any Material with Sublimation?

A5. While sublimation can be used on a wide range of materials, it works best on polyester and polymer-coated substrates. These materials have a porous surface that allows the ink to penetrate and create a vibrant image.

Q6. How Can I Fix Sublimation Prints with Color Shifting?

A6. If your dye-sub prints exhibit color shifting, try recalibrating your printer and using color profiles optimized for your specific ink and material. This should help bring the colors back in line with your design.