In the ever-evolving world of printing technology, sublimation printers have emerged as powerful tools for creating vibrant and long-lasting prints on various surfaces. Whether you’re a business owner, an artist, or a hobbyist, understanding the intricacies of sublimation printer maintenance and troubleshooting is essential for ensuring top-notch print quality and minimizing downtime.

Sublimation printers, like any other piece of machinery, require regular care and attention to perform at their best. In this comprehensive guide, we’ll walk you through the ins and outs of sublimation printer maintenance and troubleshooting. From routine upkeep to addressing pesky issues that may arise, we’ve got you covered. Let’s dive right in!

Sublimation Printer Maintenance and Troubleshooting

Sublimation printers are precision instruments, and proper maintenance is key to their longevity and performance. In this section, we’ll explore various aspects of maintenance to keep your sublimation printer in optimal condition.

1. Cleaning the Print Head

One of the most crucial aspects of sublimation printer maintenance is keeping the print head clean. Over time, ink residue and dust can accumulate on the print head, affecting print quality. Here’s how to do it:

- Power Off: Ensure the printer is powered off and unplugged before cleaning.

- Remove the Cartridges: Take out the ink cartridges carefully.

- Clean the Head: Use a lint-free cloth or cleaning solution recommended by the manufacturer to gently clean the print head.

- Check for Clogs: Inspect the print head for any clogs or dried ink. If you spot any, use a cleaning solution and a soft brush to remove them.

- Reassemble: Reinsert the ink cartridges and power on the printer.

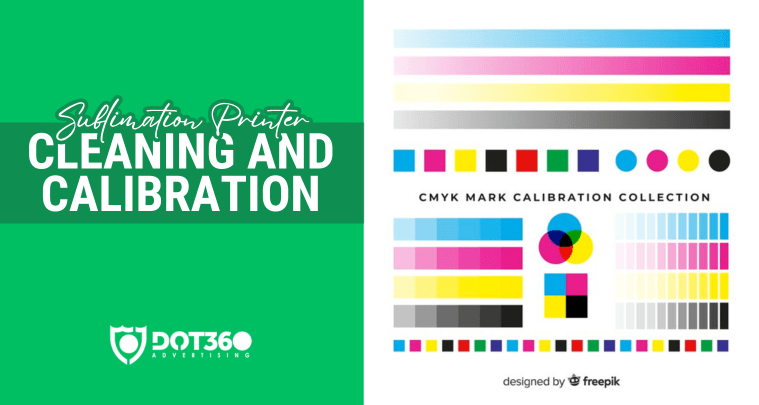

2. Calibrating Colors

Color accuracy is vital in sublimation printing. Regularly calibrating your printer ensures that the colors in your prints match your expectations. Here’s how:

- Access Calibration Settings: Go to your printer’s settings menu and find the color calibration option.

- Print Test Patterns: Follow the on-screen instructions to print color test patterns.

- Adjust as Needed: Analyze the test patterns and make adjustments to the color settings until they match your desired colors.

- Save Calibration Profile: Save the calibration profile for future use.

3. Paper Feed Maintenance

A common issue with sublimation printers is paper jams. Prevent these frustrating incidents with proper paper feed maintenance:

- Use Quality Paper: Ensure you’re using high-quality sublimation paper designed for your printer.

- Inspect Rollers: Regularly check and clean the paper feed rollers for debris or adhesive residue.

- Adjust Paper Guides: Make sure paper guides are correctly aligned to prevent misfeeds.

- Replace Worn Parts: If rollers or other parts are worn, replace them according to the manufacturer’s guidelines.

4. Temperature and Humidity Control

Sublimation printing is sensitive to temperature and humidity. Maintaining the right environment is critical:

- Temperature: Ensure your printer operates in a room with a stable temperature between 68°F to 75°F (20°C to 24°C).

- Humidity: Maintain humidity levels between 40% and 60% to prevent issues like ink drying too quickly or not adhering properly.

- Use a Hygrometer: Invest in a hygrometer to monitor humidity levels in your printing area.

- Humidifier/Dehumidifier: Consider using a humidifier or dehumidifier to adjust humidity as needed.

5. Software Updates

Printer manufacturers often release firmware updates to improve performance and address bugs. Keep your sublimation printer up to date:

- Check for Updates: Periodically check the manufacturer’s website for firmware and driver updates.

- Follow Instructions: Follow the provided instructions carefully when updating your printer’s software.

- Backup Settings: Before updating, back up your printer settings to avoid configuration loss.

6. Regular Ink Replacement

Maintaining a fresh supply of ink is essential for high-quality prints:

- Monitor Ink Levels: Keep an eye on ink levels through your printer’s software.

- Replace in a Timely Manner: When ink levels are low, replace cartridges promptly to avoid print quality issues.

- Use Genuine Ink: Always use genuine manufacturer-recommended ink cartridges.

- Priming the Cartridges: Follow manufacturer instructions to prime new cartridges properly.

7. Storage and Shutdown

If you need to store your sublimation printer or shut it down for an extended period, follow these steps:

- Properly Clean: Clean the printer as instructed earlier in this guide.

- Unplug: Disconnect the printer from the power source to prevent electrical issues.

- Cover: Use a printer cover or a plastic bag to protect it from dust and debris.

- Store Vertically: If possible, store the printer vertically to avoid ink leakage.

- Regularly Power On: Periodically power on the printer to prevent ink from drying in the nozzles.

By following these maintenance steps, you can extend the life of your sublimation printer and maintain consistent print quality. However, even with proper care, issues may arise. Let’s delve into troubleshooting common problems.

Troubleshooting Sublimation Printer Issues

Sublimation printers can encounter various issues, from poor print quality to connectivity problems. Here, we’ll address some common problems and how to resolve them.

8. Print Quality Issues

If your prints aren’t coming out as expected, consider the following solutions:

- Clean the Print Head: Refer to maintenance point #1 above to clean the print head.

- Check Ink Levels: Ensure ink levels are sufficient and cartridges are correctly installed.

- Calibrate Colors: Review calibration settings (maintenance point #2) for accurate colors.

- Use Quality Paper: Ensure you’re using the right sublimation paper (maintenance point #3).

9. Paper Jams

Paper jams are a common nuisance. Here’s how to tackle them:

- Power Off: Turn off the printer and unplug it.

- Remove Paper: Gently remove jammed paper from the printer, following the manufacturer’s guidelines.

- Inspect Rollers: Check