In the realm of sublimation printing, where creativity knows no bounds, one often overlooked but critical aspect is choosing the right sublimation paper. Whether you’re a seasoned pro or just embarking on your sublimation journey, the choice of dye-sub transfer sheet can make or break your printing projects.

In this comprehensive guide, we dive deep into the world of sublimation paper, exploring its types, qualities, and the key factors to consider when making your selection. With expert insights and answers to frequently asked questions, you’ll gain the knowledge needed to ensure your sublimation prints are nothing short of stunning.

Choosing the Right Sublimation Paper

When it comes to sublimation printing, selecting the perfect paper is akin to choosing the right canvas for a masterpiece. Let’s embark on this journey of discovery to unveil the secrets of Choosing the Right Sublimation Paper.

Understanding Sublimation Printing

Before delving into the specifics of dye-sub transfer sheet, it’s crucial to understand the sublimation printing process itself. Sublimation printing is a method that transforms a solid ink into a gas, allowing it to bond with the fibers of a substrate. This process results in vibrant, long-lasting prints on materials such as textiles, ceramics, and more.

Now, let’s explore the factors that play a pivotal role in choosing the right dye-sub transfer sheet.

The Role of Sublimation Paper

Sublimation paper serves as the carrier for your designs during the heat transfer process. It’s the intermediary between your digital design and the final product. Here’s why choosing the right dye-sub transfer sheet is essential:

- Image Quality: The type of paper you choose directly impacts the sharpness, vibrancy, and overall quality of your sublimation prints.

- Color Accuracy: Different papers can affect color reproduction. Choosing the wrong paper might result in your prints looking different from what you envisioned.

- Durability: The durability of your prints depends on the paper’s ability to hold the ink and withstand wear and tear.

- Ink Usage: Efficient dye-sub transfer sheet ensures that your ink is used optimally, reducing costs and waste.

Now that we’ve established the importance of selecting the right dye-sub transfer sheet, let’s explore the types of dye-sub transfer sheet available.

Types of Sublimation Paper

Sublimation paper comes in various types, each tailored to specific applications. Understanding these types will help you make an informed choice:

1. Standard Sublimation Paper

Standard sublimation paper is the go-to choice for most sublimation projects. It’s versatile, suitable for a wide range of substrates, and offers good color reproduction. It’s ideal for custom apparel, promotional items, and personalized gifts.

2. Tacky Sublimation Paper

Tacky dye-sub transfer sheet has a tacky coating that holds the transfer sheet in place during the heat press process. This is particularly useful when working with intricate or multi-piece designs, as it prevents shifting and misalignment.

3. Textile Sublimation Paper

Textile dye-sub transfer sheet is specially designed for fabric printing. It has a higher ink absorption rate, ensuring vibrant colors and soft, breathable prints on textiles.

4. Hybrid Sublimation Paper

Hybrid sublimation paper is a blend of standard and tacky paper. It offers the versatility of standard paper while providing the added benefit of tackiness for more complex projects.

Now that you’re familiar with the types of dye-sub transfer sheet, let’s delve into the qualities that set exceptional dye-sub transfer sheet apart.

Qualities of Exceptional Sublimation Paper

Not all sublimation papers are created equal. Exceptional dye-sub transfer sheet possess specific qualities that contribute to outstanding prints:

1. Quick Drying

Exceptional dye-sub transfer sheet dries quickly, preventing ink smudging and ensuring precise image reproduction.

2. High Ink Capacity

The paper should have a high ink-holding capacity, allowing for vibrant and detailed prints.

3. Consistency

Consistency in paper quality ensures uniform prints from start to finish, avoiding variations in color or clarity.

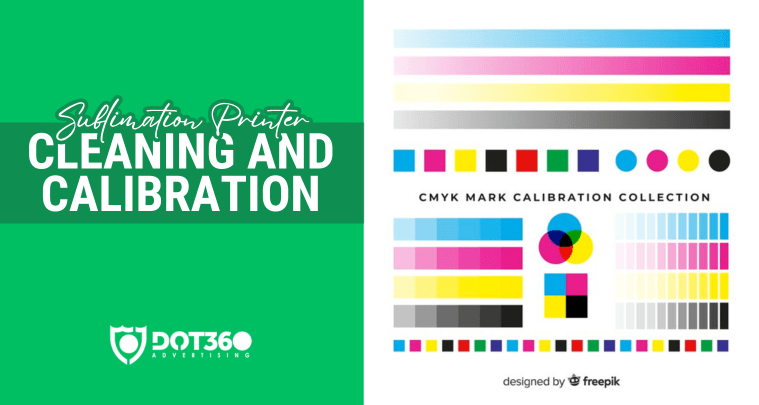

4. Compatibility

Choose a sublimation paper that’s compatible with your sublimation printer and heat press machine for seamless printing.

Now that you know what to look for in dye-sub transfer sheet, let’s address some common questions that can arise during the selection process.

Conclusion

Choosing the right sublimation paper is an art in itself, one that can elevate your sublimation printing projects to new heights. By understanding the types, qualities, and factors that come into play, you can ensure that every print you produce is a masterpiece.

So, whether you’re crafting custom apparel, personalized gifts, or vibrant promotional items, remember that the key to picture-perfect prints lies in Choosing the Right dye-sub transfer sheet. Make your selection wisely, and let your creativity shine through every sublimation print you create.

Frequently Asked Questions (FAQs)

Q1: Can I use any paper for sublimation printing?

A1: No, sublimation requires a specific dye-sub transfer sheet designed to handle the ink-to-gas transformation during the heat transfer process. Using regular paper will not yield the same results.

Q2: How do I determine the right dye-sub transfer sheet for my project?

A2: Consider factors such as the substrate you’re printing on, the level of detail in your design, and the equipment you’re using. Match these factors with the type and qualities of dye-sub transfer sheet to make an informed choice.

Q3: Are there any tips for preventing color discrepancies in sublimation prints?

A3: Ensure your sublimation paper is of high quality and matches the intended substrate. Calibrate your printer and monitor regularly to maintain color accuracy.

Q4: Can I reuse dye-sub transfer sheet?

A4: dye-sub transfer sheet is designed for single-use. Attempting to reuse it will result in diminished print quality.

Q5: What’s the difference between dye-sublimation and regular dye-sub transfer sheet?

A5: Dye-sublimation paper is specifically designed for use with dye-sublimation printers, which use dye-based inks. Regular dye-sub transfer sheet is compatible with printers that use pigment-based inks.

Q6: Can I use sublimation paper for both dark and light-colored fabrics?

A6: Sublimation paper is typically designed for light-colored fabrics. For dark fabrics, you may need to explore other transfer methods like heat transfer vinyl.