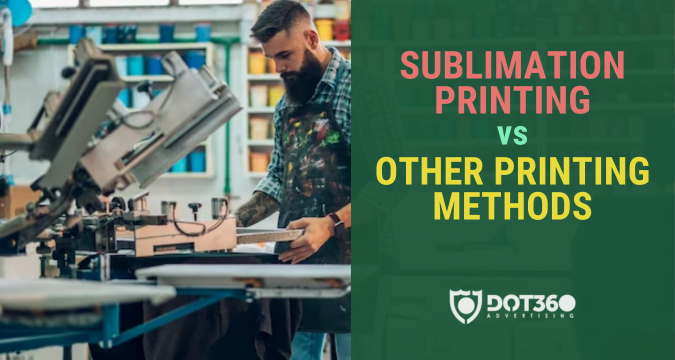

When it comes to sublimation printing, the right heat press machine is an indispensable tool for achieving high-quality and durable prints on various materials. From textiles to ceramics and metal, the heat press machine plays a pivotal role in the sublimation process. In this comprehensive guide, we’ll delve into everything you need to know about heat press machines for sublimation printing, from understanding how they work to choosing the best one for your printing needs.

Understanding Heat Press Machines

A Heat Press Machines for Sublimation is a specialized device that applies heat and pressure to transfer sublimation ink from a printed transfer paper onto the intended material. The heat and pressure cause the ink to sublimate, infusing it into the material’s fibers, resulting in vivid, long-lasting prints with exceptional color vibrancy and sharpness.

Types of Heat Press Machines

Clamshell Heat Press

The clamshell design is user-friendly and space-efficient. Its hinge mimics a clamshell, allowing for easy access to the substrate and transfer paper. This design is excellent for beginners and small-scale operations.

Swing-Away Heat Press

The swing-away heat press has a top platen that swings to the side, providing easy access to the lower platen. This design is versatile and allows for precise alignment.

Drawer Heat Press

The drawer heat press has a unique design where the top platen is pulled out like a drawer, making it suitable for bulky or heavy materials.

Auto-Open Heat Press

An auto-open heat press automatically releases the pressure once the preset time is reached, preventing over-pressing and ensuring consistent results.

Selecting the Right Heat Press Machine

- Printing Volume and Size

Consider the size of the heat press machine and its platen to ensure it can accommodate the materials you’ll be printing on and handle your desired printing volume. - Heat and Pressure Control

Look for a heat press machine with adjustable heat and pressure settings, allowing you to fine-tune the printing process for different materials. - Digital Display and Timer

A heat press machine with a digital display and timer provides precise control over the printing process, ensuring accurate and repeatable results. - Even Heat Distribution

Opt for a heat press machine with even heat distribution across the platen, preventing hotspots and ensuring consistent prints. - Safety Features

Consider machines with safety features like auto-open functionality to prevent accidents and protect both the operator and the material. - Versatility and Adaptability

Choose a heat press machine that can handle a wide range of materials, allowing you to explore various printing opportunities.

Heat Press Maintenance and Safety

- Regular Cleaning

Clean the heat press regularly to remove ink residues and debris, maintaining optimal performance. - Temperature Calibration

Periodically check and calibrate the heat press machine’s temperature to ensure accuracy. - Safety Precautions

Always follow safety guidelines and wear protective gear while using the heat press machine.

Conclusion

A high-quality heat press machine is a game-changer for sublimation printing, enabling you to create stunning and durable prints on various materials. By understanding the types and factors to consider when selecting a heat press machine, you can make an informed choice that aligns with your printing needs and creative aspirations. With the right heat press machine in your arsenal, you’ll unleash the full potential of your sublimation printer and produce exceptional prints that leave a lasting impression.

Frequently Ask Questions (FAQ)

Q1: What is a heat press machine, and how does it work in sublimation printing?

A1: A heat press machine applies heat and pressure to transfer sublimation ink from paper onto materials, creating vibrant prints.

Q2: What are the main types of heat press machines available?

A2: The main types include clamshell, swing-away, drawer, and auto-open heat press machines, each with unique features.

Q3: How do I choose the right heat press machine for my sublimation printing needs?

A3: Consider factors like printing volume, size, heat and pressure control, digital display, safety features, and material versatility.

Q4: What materials can I print on using a heat press machine for sublimation?

A4: Heat press machines work on various materials, including textiles, ceramics, metals, and more.

Q5: How does even heat distribution in a heat press machine affect the printing process?

A5: Even heat distribution ensures consistent prints without hotspots, contributing to high-quality results.

Q6: What safety precautions should I take when using a heat press machine?

A6: Follow safety guidelines, wear protective gear, and use machines with safety features like auto-open functionality.

Q7: Can I adjust the heat and pressure settings on a heat press machine?

A7: Yes, most heat press machines offer adjustable heat and pressure settings for different materials and printing requirements.

Q8: How do I maintain and clean a heat press machine for optimal performance?

A8: Regularly clean the machine to remove ink residues and debris, and periodically calibrate the temperature for accuracy.

Q9: Is a digital display and timer important in a heat press machine?

A9: Yes, a digital display and timer provide precise control over the printing process, ensuring accurate and repeatable results.

Q10: Are heat press machines versatile enough for various sublimation printing projects?

A10: Heat press machines are versatile and can handle a wide range of materials, offering opportunities for creative printing projects.